Views: 0 Author: Site Editor Publish Time: 2025-07-04 Origin: Site

Residential solar power is no longer a niche technology—it has become a mainstream solution for homeowners seeking to lower energy bills, reduce carbon footprints, and take advantage of government incentives. In many regions, houses with pitched, tile-clad roofs represent a significant portion of the housing stock. Clay, concrete, slate, and synthetic tiles are prized for their durability and aesthetic appeal, but they also present unique challenges for solar installers. A brittle tile can crack under uneven pressure, and improperly sealed penetrations can lead to costly roof leaks.

At their core, tile roof mounting systems serve three primary objectives:

Secure Attachment

Anchoring solar panels firmly to the roof's structural members—rafters or battens—so they withstand wind uplift, snow loads, and seismic forces.

Even Load Distribution

Spreading the weight of the solar array across multiple attachment points and preventing concentrated stress on individual tiles.

Leak Prevention

Maintaining the roof's waterproof envelope by integrating flashing, gaskets, and sealants that keep moisture out, both during installation and throughout the system's lifetime.

Tile roof systems come in three common variants:

Direct Mount (Hook Under Tile): Brackets or hooks slide beneath existing tiles and bolt through the underlayment into the rafter.

Tile Replacement Mounts: Entire tiles are removed and replaced with pre-fabricated base plates that mimic the tile profile and provide integrated flashing.

Hybrid Solutions: A combination of custom hooks and partial tile replacement to accommodate complex roof shapes or architectural details.

Each approach balances aesthetic considerations, ease of installation, and waterproofing performance. Choosing the right style depends on tile type, installer preference, and project requirements.

A robust tile roof mounting system comprises several integrated components that collaborate to secure panels safely and keep roofs dry:

Function: Provide the primary structural connection by hooking under a tile's lower lip or replacing the tile entirely.

Design Variations:

Custom Hooks: Precision-formed to match a specific tile profile (e.g., S-tiles, mission barrel, flat interlock).

Universal Brackets: Adjustable arms and slotted wings that conform to multiple tile shapes.

Operation:

Slide custom hooks beneath tiles without drilling into the tile surface.

For replacement mounts, remove the tile and insert a base plate flush with surrounding tiles.

Bolt the hook or bracket into the rafter or batten, transferring loads away from the fragile tile layer.

Function: Prevent water from entering at the roof penetration points.

Components:

Aluminum Flashing Plates: Contoured to match tile profiles, they sit beneath tiles and over the underlayment.

EPDM Gaskets: Rubber washers that seal around fastener heads.

Butyl Tape: Wraps the bolt shank before insertion, providing a secondary seal.

UV-Stable Silicone: Applied over flashing edges and bolt heads as a tertiary barrier.

Operation:

Flashing integrates with the tile overlap pattern to divert rainwater away.

Gaskets compress under torque to seal the fastener.

Multiple sealing layers ensure long-term leak prevention even under temperature extremes.

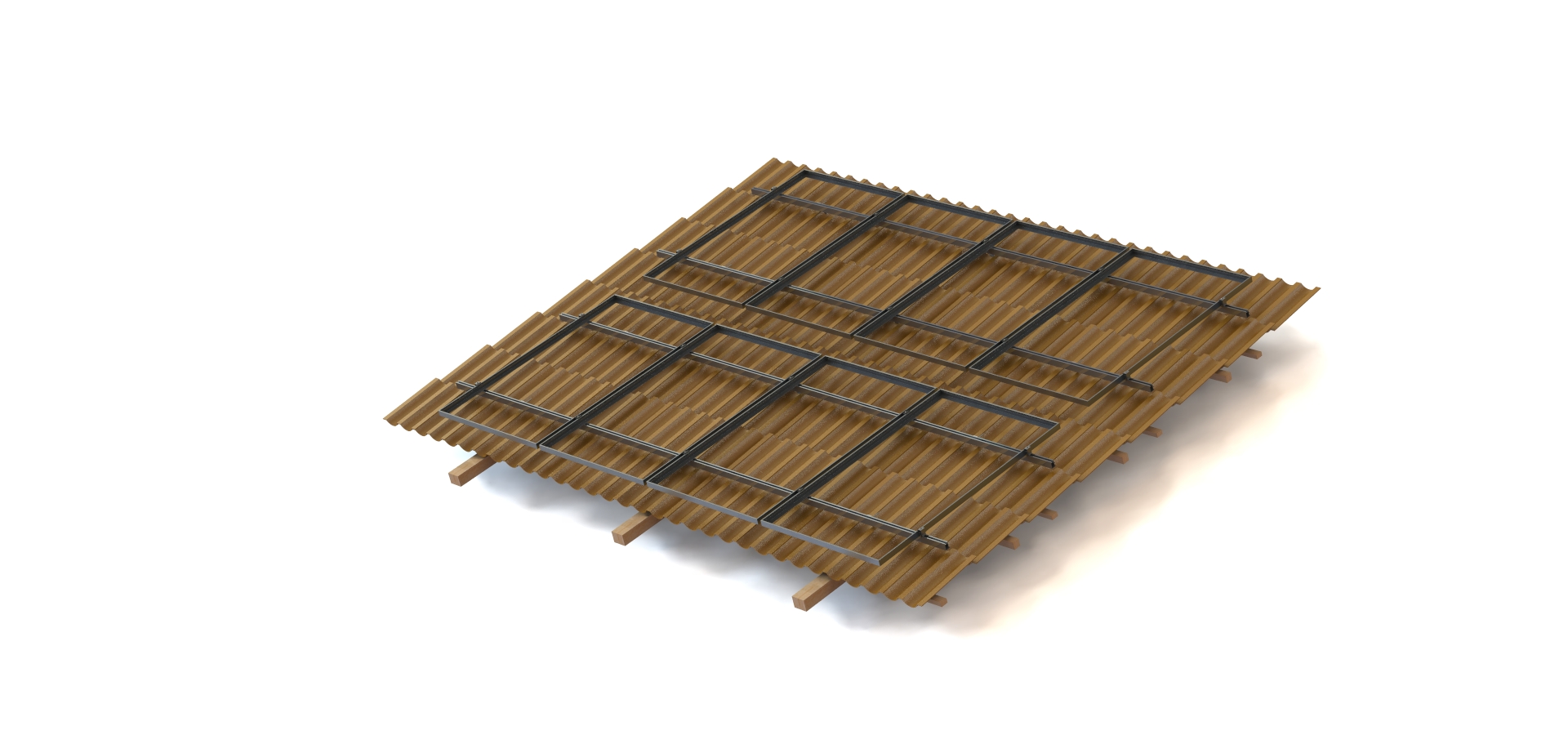

Function: Support and secure the PV modules above the tile field.

Components:

Mounting Rails: Anodized aluminum profiles that span between brackets.

Mid-Clamps: Grip adjacent panel edges to hold modules in place.

End-Clamps: Secure the outer edges of the first and last panels.

Operation:

Rails slot onto bracket heads and lock in place with rail bolts.

Clamps slide into rail channels and tighten to specified torque—ensuring even pressure along panel frames.

Rails and clamps maintain consistent panel spacing and alignment for optimal appearance and performance.

Function: Provide mechanical pull-out resistance and shear strength.

Components:

Stainless-Steel Lag Bolts: Commonly ¼″–5⁄16″ diameter, long enough to penetrate at least 2½″ into structural wood.

Toggle Bolts (for metal battens): Use spring-loaded wings for secure anchoring when wood framing is absent.

Operation:

Fasteners should never anchor only into tile or underlayment; they must embed into a rafter or secure batten.

Torque values specified by the manufacturer ensure sufficient clamp pressure without over-compressing gaskets.

Wire Management Clips: Prevent cables from vibration damage or UV exposure.

Microinverter/Optimizer Mounts: Provide accessory brackets that attach to the same rails.

Tilt Legs: Raise panels at non-flush angles for better winter performance or rooftop shading.

Together, these components form a cohesive system that physically secures panels and preserves roof integrity.

A reliable tile roof mounting system follows a structured installation workflow designed to protect tiles, maintain waterproofing, and achieve code-compliant anchoring:

Tile Removal and Inspection

Mark bracket locations over underlying rafters (using plans or a stud finder).

Carefully lift and remove the target tile(s) without damaging adjacent tiles.

Inspect the underlayment—repair or replace any damaged sections to ensure a solid base for flashing.

Bracket or Hook Installation

Insert the tile hook or base plate under the tile or into the tile replacement cavity.

Align the bracket over the marked rafter or batten location.

Place butyl tape around the hole and slide on the EPDM gasket.

Drive the lag bolt to the specified torque, compressing the gasket but avoiding over-tightening.

Waterproof Flashing Application

Position the flashing plate so its contoured profile matches the tile shape.

Ensure at least 2″ overlap with adjacent underlayment and tiles.

Seal flashing edges with a bead of UV-resistant silicone.

Tile Cutting or Replacement

For direct hooks, slide the original tile back into place, ensuring the hook exits through a pre-cut notch.

For replacement mounts, install the prefabricated base tile in lieu of the removed tile.

Re-seat surrounding tiles to maintain proper interlock and drainage.

Rail Mounting and Panel Alignment

Snap or bolt mounting rails onto bracket heads.

Use a level or laser to ensure rails run straight and true.

Secure mid- and end-clamps at calibrated torque, checking for panel frame compression without deformation.

Electrical and Finishing Touches

Route cables through wire management clips.

Inspect all flashing and sealant beads for completeness.

Perform a water test—spray each bracket for several minutes to confirm no leakage under the flashing.

Each step emphasizes minimal tile disruption and maximum waterproofing, ensuring that the solar array functions safely and the roof remains leak-free.

Choosing a proper tile roof mounting system is not merely a matter of convenience—it directly impacts the project's success from both performance and warranty standpoints:

Structural Protection

A well-engineered system transfers loads into the roof structure, not the fragile tiles. This prevents tile cracking, detachment, and premature roof replacement.

Weatherproofing Integrity

Integrated flashing and multi-layer seals preserve the underlayment's waterproofing function. Improper roof penetrations are the leading cause of installation-related leaks.

Durability and Safety

Components rated for high wind speeds (e.g., 60 m/s) and snow loads (e.g., 1.4 kN/m²) ensure panels remain secure under extreme weather, safeguarding both property and lives.

Regulatory Compliance

Certified mounting systems meet building code requirements and often satisfy manufacturer warranty terms—critical for insurance and financing programs.

Aesthetic Considerations

Low-profile hooks, color-matched flashing, and precise alignment preserve a home's curb appeal—essential in aesthetic-sensitive neighborhoods.

In short, these systems matter because they protect the homeowner's investment, maintain the integrity of the roof, and ensure that the solar installation performs reliably over decades.

When evaluating tile mounting options, consider these factors:

Tile Material & Profile: Match hardware to the exact tile shape—never force a mismatched hook under a tile.

Wind & Snow Requirements: Select systems tested to local code parameters for wind uplift and snow load.

Material Selection: Opt for marine-grade aluminum or stainless steel in corrosive environments.

Installation Support: Work with suppliers—like SINPO METAL—that provide compatibility charts, torque guides, and on-site training.

Warranty & Service: Confirm that both components and seals carry long-duration warranties and that replacement parts are readily available.

By thoroughly assessing these criteria, you'll minimize risk, streamline installation, and maximize system longevity.

Residential Showcase: A suburban home with Spanish barrel tiles installed a custom hook system with preformed aluminum flashing. Over three years, no leaks or tile damage occurred, and the panels maintained perfect alignment despite monsoon-level rains.

Small Commercial Roof: A café with concrete interlock tiles utilized universal adjustable mounts to accommodate slight tile profile variations. The system achieved code-compliant wind ratings and completed installation in half the time of older methods—boosting return on investment through labor savings.

Installer Testimonial:

“Switching to a purpose-built tile system cut our callbacks for leaks by 90% and improved our install average from 6 minutes per hook to under 4. The training materials and compatibility guides were game-changers for our crew.”

– SolarEdge Installers, San Diego, CA

These examples underscore how the right system enhances reliability, installation speed, and customer satisfaction.

Tile roof mounting systems are the linchpin of successful solar installations on tile clad homes. By securing panels to structural members, distributing loads safely, and preserving the roof's waterproof envelope, they deliver peace of mind for homeowners and profitability for installers.

To summarize:

Define Your Roof Type: Identify tile material and profile.

Select the Appropriate Hardware: Custom hooks for exact fit; universal mounts for versatility; replacement assemblies for seamless integration.

Verify Structural and Waterproof Credentials: Check certifications and warranty terms.

Streamline Installation: Use pre-assembled kits, clear guides, and proper torque tools.

Partner with Experts: Leverage suppliers like SINPO METAL for technical support, compatibility charts, and product training.

For more information on tile roof mounting solutions—detailed datasheets, CAD models, and installation resources—visit www.sinpo-metal.com. With the right system in place, your solar panels will not only generate clean energy but also rest securely on a watertight foundation for decades to come.