Solar Panel Frames Made of Aluminum Profile

A. Lightweight and Strong Structure

Aluminum profiles are widely used to make the frames of solar panels. Their lightweight nature makes it easier to install and handle the solar panels, reducing the labor and cost involved in the installation process. At the same time, the high strength-to-weight ratio of aluminum profiles ensures that the frames can support the weight of the solar panels and withstand various environmental conditions, such as wind, rain, and snow.

B. Corrosion Resistance for Outdoor Use

Solar panels are usually installed outdoors, where they are exposed to the elements. Aluminum profiles' corrosion resistance is a significant advantage in this regard. The oxide layer on the surface of the aluminum profiles protects them from rust and other forms of corrosion, ensuring that the solar panel frames remain in good condition for a long time. This extends the lifespan of the solar panels and reduces the need for frequent maintenance and replacement.

Mounting Structures for Solar Energy Systems

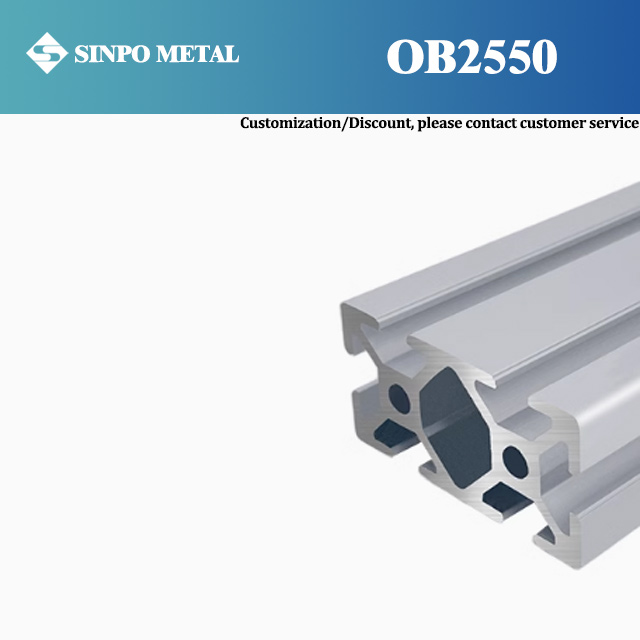

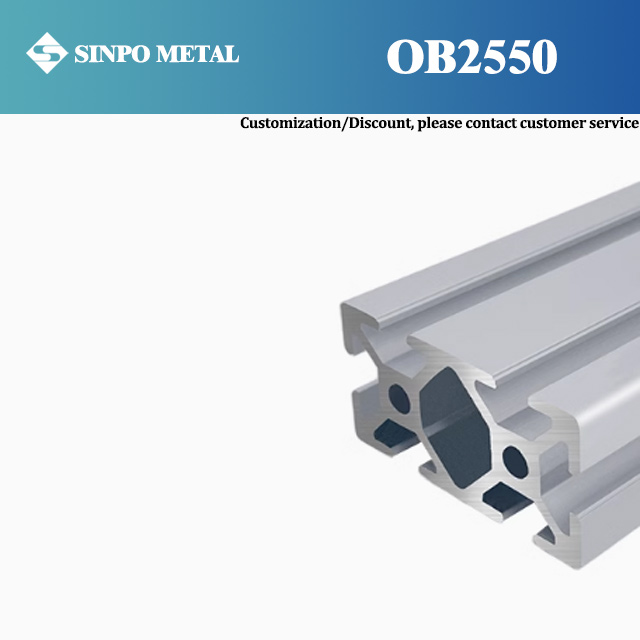

A. Customizable Mounting Solutions

Aluminum profiles can be used to create customizable mounting structures for solar energy systems. These structures can be designed to fit different installation sites and requirements, such as rooftops, ground-mounted arrays, or tracking systems. The extrusion process allows for the production of profiles with various shapes and sizes, enabling the creation of efficient and stable mounting structures.

B. Ease of Installation and Adjustment

The lightweight and modular nature of aluminum profiles make them easy to install and adjust. They can be quickly assembled using simple tools, and their components can be easily replaced or modified if needed. This flexibility is especially important for solar energy systems, which may need to be adjusted over time to optimize their performance.

Heat Dissipation in Solar Inverters

A. Aluminum Profile as Heat Sinks

Solar inverters are an essential component of solar energy systems, and they generate heat during operation. Aluminum profiles can be used as heat sinks in solar inverters to dissipate this heat effectively. Their good thermal conductivity allows for efficient heat transfer, preventing the inverters from overheating and ensuring their proper operation.

B. Improving Inverter Performance

By using aluminum profiles as heat sinks, the performance of solar inverters can be improved. Overheating can reduce the efficiency and lifespan of inverters, and effective heat dissipation helps to maintain their performance and reliability. This, in turn, contributes to the overall efficiency of the solar energy system.

Aluminum profile plays a crucial role in solar energy systems, from the frames of solar panels to the mounting structures and heat sinks in solar inverters. Its lightweight, corrosion resistance, and thermal conductivity make it an ideal material for enhancing the efficiency and durability of solar energy systems. As the solar energy industry continues to grow, the use of aluminum profiles is expected to increase further, driving the development of more advanced and efficient solar energy solutions.